About 40 percent of the overall cost of recycling, according to one recent study, is transportation. The harder part is getting dead batteries to those facilities from wherever they met their demise. The recycling process typically involves shredding batteries, then breaking them down further with heat or chemicals at dedicated facilities. “People don’t know the risks involved.”Įxtracting the valuable materials from an EV battery is difficult and expensive. “The voltages in these batteries are lethal,” says Latham, who trains salvagers just getting started with EVs. Lithium-ion battery packs are, by contrast, heavy machines with dozens of components and radically different designs depending on their manufacturer. More than 95 percent of them are recycled today because consumers can claim deposits when they return the batteries, and they are relatively simple to dismantle. That includes the lead-acid batteries that start gas-powered cars. Dismantlers-including those that fly under the radar of regulators-make a fine art of wringing every penny from a dead car, explains Andy Latham, CEO of Salvage Wire, an auto recycling consultancy in the UK. Today’s system mostly works because scrap metal has value and there’s a healthy market for conventional auto parts. “These vehicles go to auction and anybody can grab them,” Kendall says. When it finally dies, it falls into a globe-spanning network of auctioneers, dismantlers, and scrap yards that try to dispose of cars as profitably as possible. Cars are typically globe-trotters the average vehicle may have three to four owners and cross international borders in its lifetime. One thing appears certain: The current way of dealing with cars past their prime won’t cut it. Spiers New Technologies takes flawed batteries and transports, tests, and-when possible-disassembles, fixes, and refurbishes them.

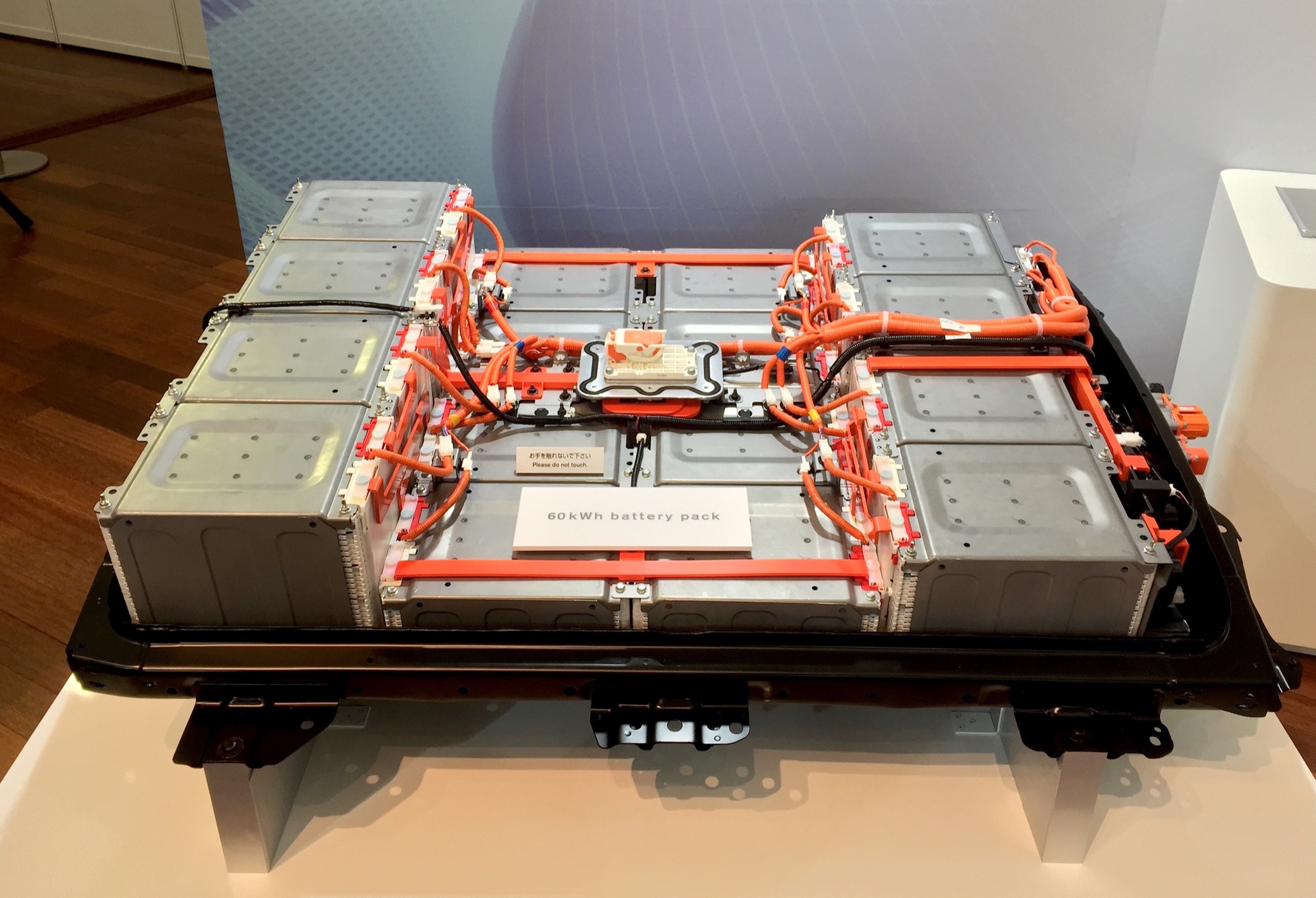

Spiers turned that opening into a business that now handles the logistics of dead and dying EV batteries from every major carmaker that sells in the US, except Tesla. His relationship with GM had begun 11 years earlier, when he buttonholed the company’s head of development for an earlier electric vehicle, the Volt, about GM’s plan for the batteries when they broke or died. Spiers was a natural person to call for help. When taken apart for repairs, they can be dangerous, and incorrect handling can lead to noxious fumes and fires. It contains hundreds of battery cells that are delicate and finicky.

#ELECTRIC CAR BATTERY COST FULL#

Unlike the toaster-oven-sized lead-acid batteries inside most gas-powered vehicles, the lithium-ion battery pack inside the Bolt runs the full wheelbase of the car and weighs 960 pounds. Fixing them would be a massive operation. Now the automaker was expanding the recall to all 141,000 Bolts sold worldwide since 2017.

0 kommentar(er)

0 kommentar(er)